Rika Sensor es un fabricante de sensores meteorológicos y proveedor de soluciones de monitoreo ambiental con más de 10 años de experiencia en la industria.

How to Calculate Wind Speed with an Anemometer?

Leon Battista Alberti, around 1450, created the first-ever mechanical device for measuring wind speed (anemometer), highlighting humans' centuries-long efforts to find airspeed. The massive application of anemometers in the modern era, along with wide-scale industrialization and advancements in avionics, makes them essential for the survival of civilizations. Anemometers play a crucial role in calculating the speed of a flying jet and finding the right time for industrial stack discharge.

The method for calculating wind speed using an anemometer depends on its type and working mechanism. This article will start with the basics of anemometers, their types, working mechanisms, applications, wind speed calculation methodology, and tips for maintaining anemometers. Let's begin with basic anemometer sensors!

Understanding Anemometers: What They Are and Why They Matter

An anemometer is a device that provides air speed and sometimes direction through a mechanical or electronic mechanism. Depending on their design and application, anemometers can be handheld or inline. They may calculate the windspeed using drag force, dynamic head, heat transfer, or sound delay.

As mentioned earlier, humans have been striving to calculate wind speed as it was vital for ship sails and navigation. With time, humans have found use of anemometers in agriculture, architecture, and early weather forecasting. These are the key sectors for the modern era.

Types of Anemometers: From Cup to Ultrasonic

Anemometers come in various configurations and working mechanisms. The purpose of all types is to measure airspeed. However, some may be more accurate, while others may be suitable for large-scale applications. Here are the five key types of anemometers:

1 Cup Anemometers: Simplicity and Reliability

It is the most straightforward method of measuring windspeed. The anemometer consists of three or four cups, with their axis along the wind direction. The quantity of cups depends on the design and specifications. The cups offer more air resistance in one direction and lower in the other, causing them to rotate the shaft they mount on. The rotation of the shaft represents the wind speed. These are feasible for wind speeds from 0 to 70 m/s (0 to 157 mph).

2 Vane Anemometers: Directional Accuracy

As the name suggests, vane anemometers utilize vanes similar to fans to detect wind speed. Their design includes multiple vanes connected to a shaft that rotates when exposed to wind. These devices are usually handheld and meant to provide swift airspeed. In industries, these are great for HVAC, environmental, and weather studies. They provide a higher accuracy with detection capability between 0.4 to 30 m/s (80 to 5906 fpm).

3 Hot-Wire Anemometers: Precision in Low Speeds

A hot-wire anemometer utilizes heat transfer to precisely calculate wind speed at low speeds. A typical hot-wire anemometer can detect wind speeds of 15 to 30 m/s (or 30 to 5900 ft/min). It uses changing wire resistance with temperature to detect wind speed. These are available in handheld or in-line configurations.

4 Ultrasonic Anemometers: Advanced Technology

These are some of the most advanced anemometers, with many advantages over traditional windspeed measurement methods. They have no moving parts, which makes them ideal for long-term use. Their calibration requirements are minimal and produce high-precision results. They can detect wind speed and direction with ±2% accuracy. Their inherent design makes them long-lasting with little to no aging.

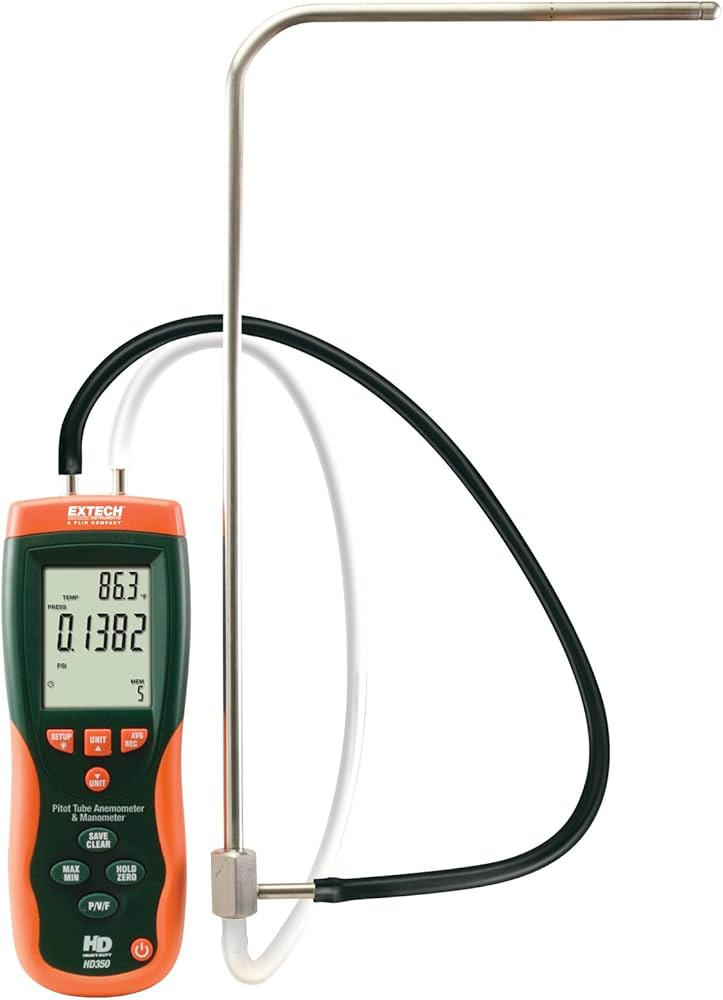

5 Pitot Tube Anemometers: High-Speed Measurement

A pitot tube detects low wind speeds by converting wind speed to pressure. It restricts the flow to zero speed, causing a rise in the pressure of the anemometer internals. The working mechanism restricts its ability to detect low wind speeds. However, it can measure the high velocity of air, typically in the range of 0 to 80 m/s, in industrial applications. Pitot tubes have been widely adopted in aircraft speed sensing.

How Anemometers Work: The Science Behind Wind Speed Measurement

Understanding the science behind the workings of these sensors and detectors can lead to their best utilization. Here is the working mechanism of these sensors:

- Principles of Rotational Anemometers

Rotational anemometers include vane-type and cup-type anemometers. They rely on rotating a shaft whose rotational speed is directly proportional to the speed of the wind. It uses mechanical components that rotate when subjected to force. The shaft rotation can provide wind speed in mechanical and electronic ways.

A rotational anemometer can have a mechanical counter that records the number of rotations, and users can convert them to speed using a mathematical model. In another case, electronic rotational anemometers convert these rotations into a direct wind speed value based on their calibration. Their mechanical nature makes them vulnerable to wear and tear.

- Thermal Anemometry: Measuring Heat Transfer

Thermal technology, like the hot-wire anemometer, uses an electric wire to check the wind speed. The resistive wire tungsten, platinum, or platinum-iridium alloy is heated using a circuit. The circuit will either maintain a constant current through the wire or a constant temperature of the wire.

- Constant Current: In fixed current, the wire heats up when current is supplied across it. When air passes over the wire, it changes its temperature, proportional to the air speed.

- Constant Temperature: In a fixed-temperature design, the circuit maintains the temperature while the air flowing over it causes the circuit to increase the current to keep the temperature. The current indicates the airspeed.

The wires going through a cyclic heating and cooling cycle will eventually cause it to fail under thermal stresses.

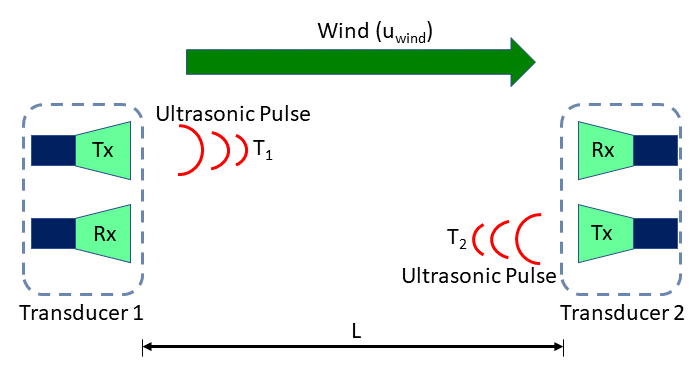

- Sonic Anemometry: Using Sound Waves

Sonic anemometers are the most advanced, reliable, accurate, robust, and long-lasting wind speed sensors. They utilize ultrasonic sound frequencies to detect windspeed. There is no need to check wind direction; the sensor detects wind speed and direction through the same set of sensors.

The sensor uses a transmitter, reflector, and receiver to check the wind speed. The time the sound travels through the air and back after reflecting represents the wind speed. A set of multiple sensors in various directions and their sound travel time change indicate wind direction. It uses the time of flight theory.

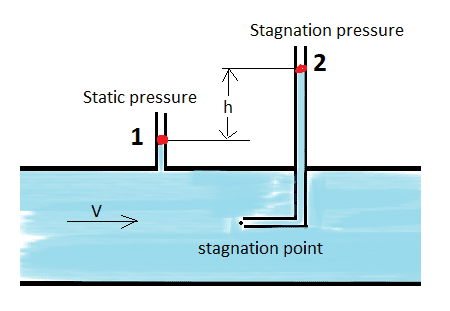

- Pressure-Based Anemometry: Pitot Tubes Explained

The most accurate and precise anemometer for high-velocity air would be a pitot tube. It has an accuracy of ±5% of full scale (FS). It utilizes the conversion phenomenon of dynamic head to static head. The Bernoulli equation explains that the static pressure will increase if you stop the flow of moving air. It's also called stagnation pressure. The intensity of this pressure indicates the velocity. A pitot tube has a small opening before the sensor that stops airflow. The pressure travels to a pressure sensor, creating a pressure signal proportional to the air velocity.

Step -by-Step Guide: How to Calculate Wind Speed with an Anemometer

Calculating wind speed using a modern anemometer is simple and quick. However, to ensure that the results are accurate and relevant to your requirements, the following steps can prove to be helpful:

Step 1: Setting Up Your Anemometer for Accurate Readings

The first step is ensuring your application matches the anemometer's specifications. Ensure that you have the right type for the right job. For wind detection in weather forecasting, use ultrasonic or cup anemometers. For HVAC or calibration purposes, use vane or hot-wire anemometers. For high-velocity air, utilize a pitot tube.

Follow the manufacturer's guidelines to ensure that your anemometer provides accurate readings. The guidelines will provide the basics of wind speed measurement, such as proper direction, holding method, mounting method, calibration checks, and maintenance. Take into account environmental factors like rain, moisture, or heat.

Step 2: Reading and Interpreting Anemometer Data

Most anemometers have an onboard display that provides the results directly. However, anemometers that provide an RS232/RS485(Modbus/NMEA-0183) or SDI-12 output will require a computer interface to interpret the results.

Step 3: Calculating Wind Speed from Raw Data

Digital data is simply a conversion of the electrical analog data in its current form. The digital data must then be converted into interpretable results (e.g., m/s, km/h, knots). For that, you need the correct conversion formulas and software. Manufacturers of anemometer sensors provide software that allows calibration and interpretation of signals.

Step 4: Troubleshooting Common Measurement Errors

Some of the standard measurement errors include:

- Wrong installation direction

- Frictional losses in mechanical anemometers

- Weather impact

- Interference in digital signal with unshielded cables

- Physical obstructions include walls, trees, buildings, etc.

- Vibrational impact

- Human errors

Observe your anemometer setup to ensure the above measurement errors do not impact your results.

Choosing the Right Anemometer: Factors to Consider

Selecting the right anemometer is also vital to ensure that the results are accurate and precise. While considering an anemometer sensor, analyze the following factors before making the purchase decision:

● Accuracy and Measurement Range

The accuracy and measurement range requirements can vary depending on the application (avionics, HVAC, weather reporting, research, etc.). Ensure that the velocity of air measurement falls within the range of your anemometer type and design. Use the following table for reference:

Type of Anemometer | Measurement Range | Accuracy |

Cup Anemometer | 0.5 to 50 m/s | ±1–3% of reading or ±0.5 m/s |

Vane Anemometer | 0.3 to 45 m/s | ±2–3% of reading or ±0.2–0.5 m/s |

Hot-Wire Anemometer | 0.1 to 100 m/s (typically < 50 m/s) | ±1% of reading (better in labs) |

Ultrasonic Anemometer | 0 to 60 m/s (some up to 100 m/s) | ±1–2% of reading or ±0.1 m/s |

Pitot Tube (Pressure Tube) | 1 to 300 m/s (high-speed flows) | ±1–5% |

● Environmental Considerations: Durability and Weather Resistance

Ultrasonic sensors can provide accurate readings in rain and harsh weather conditions. Their intrinsic design allows them to operate under all conditions. Similarly, a pitot tube can offer results in high-velocity air while remaining fully functional. Hot-wire is sensitive to moisture and dust, making it ideal for indoor use only. The cup and vane are subject to wear and tear due to moving parts. They may also require regular calibration to offset the increasing resistance in their parts.

● Specific Application Requirements

Here are some of our recommendations based on applications:

- Cup Anemometer: Meteorology, wind energy studies, weather stations, general outdoor wind monitoring

- Vane Anemometer: HVAC systems, environmental monitoring, industrial ventilation systems

- Hot-Wire Anemometer: Laboratory research, airflow studies, cleanroom monitoring, low-speed indoor airflow

- Ultrasonic Anemometer: Wind turbine control, meteorology, marine applications, harsh outdoor environments

- Pitot Tube (Pressure Tube): Aviation, wind tunnel testing, high-speed airflow measurement

● Budget and Cost-Effectiveness

Cost-effectiveness in engineering projects is vital to keep them feasible and marketable. Your project needs to be financially viable to meet the market demand. In that case, always consider the budget. Using an ultrasonic sensor with a lower range and accuracy for weather prediction can be a wise decision rather than buying an expensive rotary anemometer with higher accuracy. Consider cost before making any purchase decision.

Konkludo : Harnessing the Power of Wind Speed Measurement

Anemometers are vital to modern industrial applications. They provide precise live air velocity or wind speed measurements. Wind speed measurements from anemometers are used in weather predictions, stack discharge dispersion, HVAC systems, turbine system control, and much more. These applications require different types of anemometers, further enhancing the output, sometimes providing accuracy while sometimes emphasizing robustness.

Overall, the technology in anemometers is already evolving. Laser Doppler and ultrasonic anemometers provide measurements without mechanical movements while maintaining accuracy. The accuracy and simplification of these sensors will improve further.

If you want to explore high-end, cost-effective, and modern technology in wind speed measurement, then explore the Rika wind speed sensors . They have an extensive range of wind sensors and weather stations for varying applications. Visit their site to broaden your knowledge and exposure!

LEAVE A MESSAGE